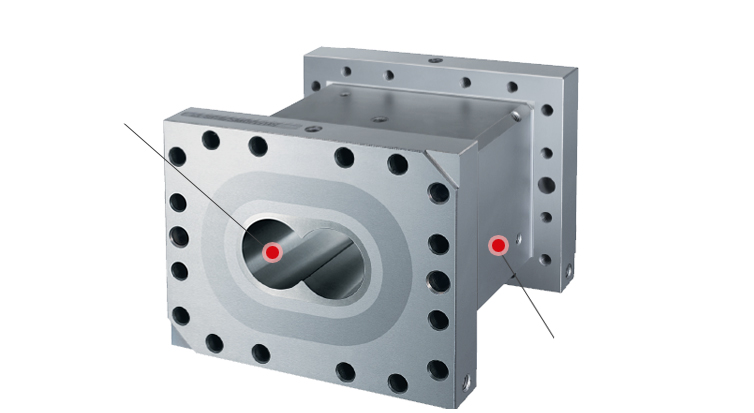

MechanismBarrel & Sleeve

Wear Protected Sleeve Type Barrel

Barrel Feature & Usage

| Name | Shape | Application |

|---|---|---|

Feed Barrel |

Top Open Feed Hopper Connection |

Raw Material Feed Zone |

Closed Barrel |

Closed Barrel | Melting Zone Reaction Zone Pressurized Zone |

Vent Barrel |

Top open Atmosphere Open Vacuum Pump Connection |

Air & Gas Exhaust Vent Port & Vacuum Pump Connect |

Side Feed Barrel |

Additive Feeding Side Feeder Connection Top & Side Plug |

Add Material Feeding Side Feeding |

Plate Barrel

Plate Barrel(Injection Type) |

Liquid nozzle port (Top or Side) |

Liquid Injection |

Specification

| Code | Material | Protection | Hardeness | Temp ( MAX. ) |

Protect against | Material | |

|---|---|---|---|---|---|---|---|

| Abrasion | Corrosion | ||||||

| Very high <-- | --> Very high | ||||||

| SM 010 | Nitrided steel | Normal Abrasion | 750 ~ 850 Hv | 450 ℃ | Nitrieded | ||

| SM 077 | Hi-Chrome Base Steel | Abrasion + | 61 ~ 63 HRc | 450 ℃ | Cr Base | ||

| SM 800V | Powder Metal | Abrasion ++ | 62 ~ 64 HRc | 450 ℃ | V Base | ||

| SM 815V | Powder Metal | Ultra Abrasion | 62 ~ 64 HRc | 450 ℃ | V Base | ||

| SM 260X | Powder Metal ( HIP ) | Abrasion + Corrosion | 60 ~ 62 HRc | 450 ℃ | V-Cr series | ||

| SM 800X | Bi- Metal ( Xaloy ) | Abrasion + Corrosion | 60 ~ 62 HRc | 450 ℃ | W-Ni serie | ||