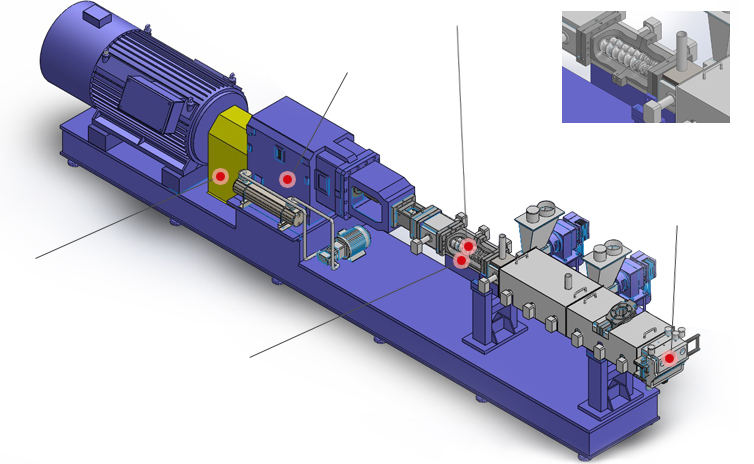

MechanismDescription of parts

TEK-MHS model is the most advanced model to achieve the high performance and high speed.

- 01Die head

-

The polymer compounded with the

extruder is discharged from the nozzle on

a die at the end of the barrel.

The polymer is cut into pellets by rotating knives and cooled in water, and transferred to the centrifugal dryer.

- 02Barrel & Sleeve

-

Barrel length and mounting position can

be configured in various ways, due to its

building block type design.

Standard barrel, Feed barrel, Vent barrel, Side feed barrel, Plate barrel can be changed according to the raw material and / or functionality requirements.

- 03Screw & Shaft

-

The function of screws includes Feeding, Melting, Mixing,

Dispersing, Congesting, Degassing and Pressurizing.

Screw metals are selected in accordance with the raw

material and additives used.

Screw elements are assembled individually in shaft to which strong power is transmitted by involutes splines.

- 04Torque Limiter

- This safety device protects the motor and the extruder by physically isolating power transmission if the rated torque or rated speed of them is exceeded.

- 05Gear Box

- Compact and low noise type gear box implements high speed and high torque. Power transmission efficiently is enhanced by adopting dual drive system. Gears are made with special alloy metal for long-term operation.