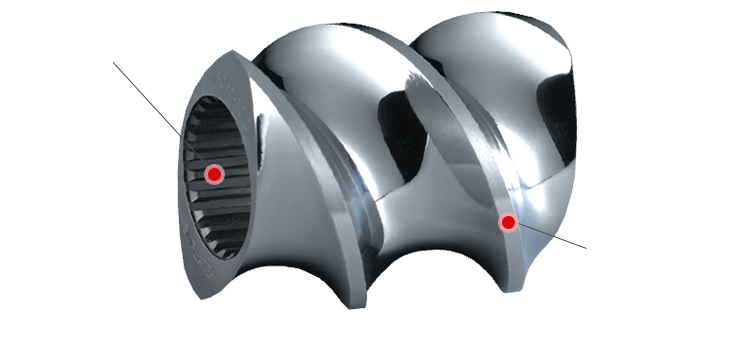

Depth Screw and Spline Shaft

Involute spline for

high power output

Various types and materials

of screws are available to

meet customers’ specific

requirement.

- SCREW (Do / Di =1.55)

-

Screw intermeshing ratio is 1.55 (Out-dia./In-dia.)

Names of the screws are shown in the figure below.

The function of the screw include feeding, melting, mixing,

dispersing, congesting, degassing and pressurizing as

illustrated in the figure.

Specification

| Code | Material | Protection | Hardeness | Temp(MAX.) | Protect against | Material | |

|---|---|---|---|---|---|---|---|

| Abrasion | Corrosion | ||||||

| Very high <-- | --> Very high | ||||||

| SM 100 | Nitrided steel | Normal | 900~1050 Hv | 450℃ | Nitrieded | ||

| SM 110 | Cr Base Tool Steel | Abrasion | 58~60 HRc | 450℃ | Cr Base | ||

| SM 111 | Cr Base Tool Steel | Abrasion | 900~1050 Hv | 450℃ | Cr Base | ||

| SM 150 | PM-HIP Compound | Abrasion + Corrosion | 60~62 HRc | 450℃ | V Base | ||

| SM 150H | PM-HIP Compound | Abrasion + Corrosion | 68~70 HRc | 450℃ | V Base | ||

dp-Type Screw (Do/Di=1.62)

Screw outer-diameter divided by inner-diameter is

called intermeshing ratio. (Typical ratio = 1.55)

With the same center distance, the intermesh-ratio is

increased from 1.55 to 1.62 to provide lager space for

material transfer.

This is suitable for the materials containing high ratio of fillers.

Materials of lower specific gravity are easy for processing.

It is possible to reduce the heat generated by the reduction of the

inner friction surface of screws and sleeves to reduce discoloration

caused by heat. It is advantageous for reaction process due to extended residence time.

Screw(Example)

| Name | Application | ||

|---|---|---|---|

| Screw |  |

SC60-60 | FeedingNormal, 2-Lobe Type |

|

SK60-60 | FeedingUndercut, 2-Lobe Type | |

|

SC60-60-1/1 | FeedingVolume Expansion, 1-Lobe Type |

|

|

SC60-30L | Feed BlockingNormal Reverse, 2-Lobe Type |

|

| Name | Application | ||

|---|---|---|---|

| KneadingBlock |  |

KB60-3N | Melting & MixingNormal, 2-Lobe,90degree |

|

KB40-5R | Melting & MixingNormal, 2-Lobe, Right | |

|

KB40-5L | Melting & MixingNormal, 2-Lobe, Left | |

|

KB40-3/3 | Melting & MixingSpecial, 3-Lobe | |